Providing global sustainable waste management & contracting solutions

What a waste!

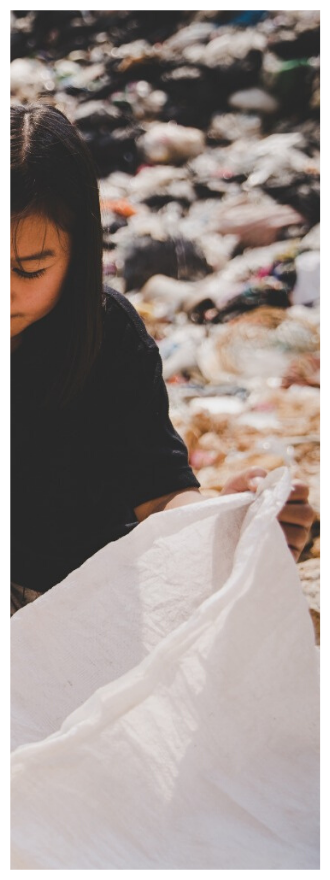

Mankind has been actively and knowingly destroying the global environment for quite some time now. Our lifestyle and drive for economic growth creates waste streams in abundance, these waste streams pollute our air, soil, surface water, groundwater and our oceans on a global scale. It is high time to act!

DutchPowerGroup provides sustainable, practical and tested solutions for the processing of waste and residual material streams, in a responsible way. We provide solutions for the growing demand for various sustainable energy sources at the same time. We can support you to evolve and innovate in the reduction of your waste impact.

More information

DutchPowerGroup provides advice and contracting on:

Waste prevention, Waste gathering, Waste deposition / landfilling, Gas extraction from landfill, Waste separation, Composting, Digestion, Processing remaining flows, Combustion technologies.

Self-owned modular incineration technology

- Chameleon (grate firing technique)

- Phenix (Fluidized bed technology)

OCEAN

AIR

OCEAN

AIR

agricultural waste

MUNICIPAL WASTE

BIOMASS

WHY

We lead the way

We actively address the topics of waste management and we provide and implement the legislation, guidelines as well as provide the hardware related to waste collection, separation and further processing technology of residual streams.

DutchPowerGroup is a leading company. Providing the specific know-how and the practical approach which leads to achieving results in the field of waste management. We underwrite the need and the urgency to act on pollution NOW!

More information

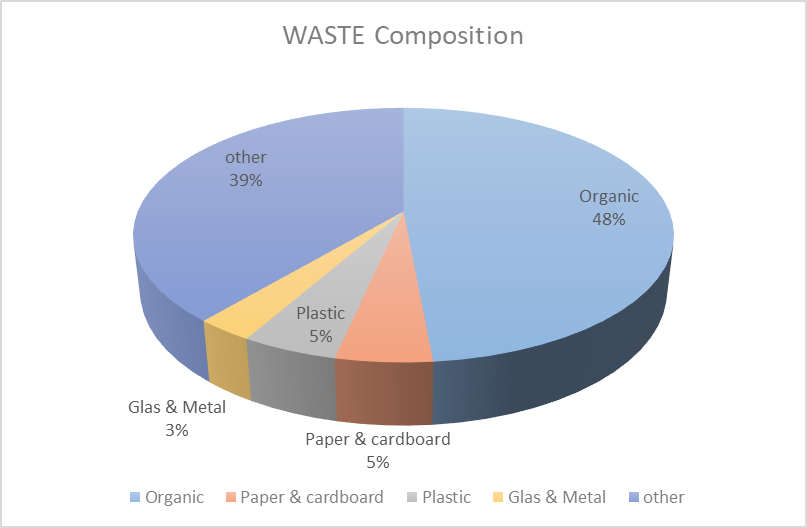

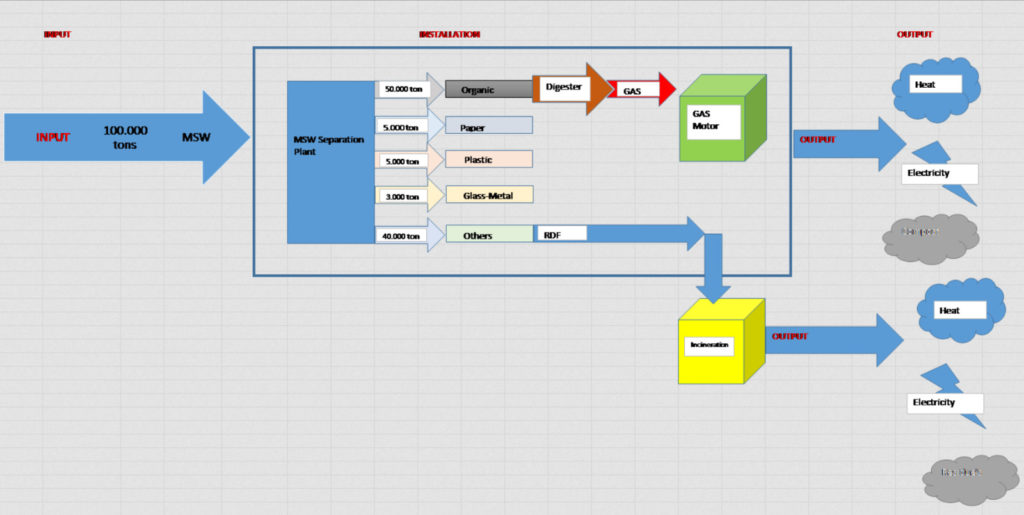

Underneath you see a pie-chart of a typical municipal waste composition. This shows that the biggest part of this type of waste consists of digestible organic material. This material does not belong on a landfill but can be digested and turned into compost and biogas. Both materials can be used effectively. The other fractions can be simply separated in a specific waste separation plant and deliver valuable stream which can be reused or recycled. The category ‘Others’ is a mixture of materials like, textiles, plastic film, fines, stones, combustibles, fibres etc.

The remains of this ‘Others’ specific municipal waste stream (after passing thru a waste separation plant) can be incinerated in a combustion system, to deliver value steam which can be turned into electricity and heat, for heat demanding production processes or for district heating systems.

Source: Janse ECM b.v. study

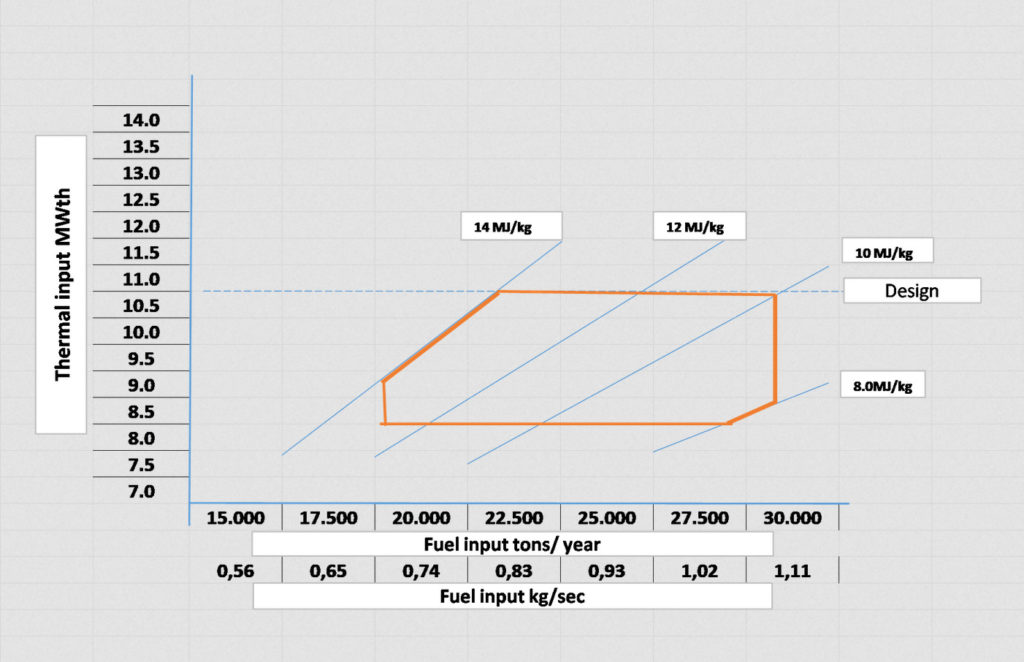

A typical combustion diagram of a RDF (Refuse Derived Fuel) incineration unit could look like a diagram as shown underneath

Source: Janse ECM b.v. Thermal design.

AGRICULTURE

MUNICIPALE WASTE

BIOMASS

“The time is always right to do what is right” – Martin Luther King

how

Waste to energy (W2E)

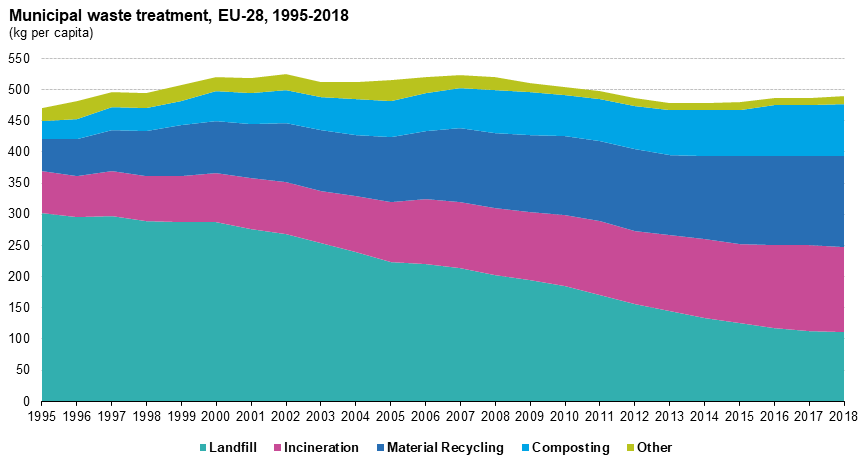

During the last decades the processing of waste has changed. In Europe, as a result of several initiatives like, re-use and recycling the amount of municipal waste which goes to a landfill is reduced by nearly 60% HOWEVER still more than 100 million tons of municipal waste are put on a landfill, to remain there for indefinite time. Emitting greenhouse gasses into the air, polluting the soil and the groundwater. DutchPowerGroup solutions are available for all challenges of waste stream management. We practically contribute to the limitation of unnecessary landfilling and the re-use valuable components within the municipal waste stream. We could even offer you a solution for ‘Urban Mining’ of your existing landfills.

DutchPowerGroup supply waste to energy installations that produce energy by incineration.

More information

In the diagram underneath the distribution of municipal waste in Europe is shown during the last decades.

Source: Eurostat

Source: Janse ECM b.v. study

In above shown diagram we show the complete waste stream handling steps which could be applicable for a specific municipal waste stream. The know-how and expierence for all shown steps are available within the DutchPowerGroup.

Fresh water

In many countries freshwater is as scarce as energy, in certain areas on the globe probably even more scarce! The rise of temperatures, drought, and groundwater pollution cause great concern in covering the daily demand. In the near future it will be a huge challenge to provide sufficient freshwater for all people. In order to meet this challenge, the production of freshwater can be part of our Waste to Water approach. In order to provide freshwater the DutchPowerGroup plants have the possibility to install active freshwater production as a run-off product of our thermal waste processing plants.

More information

Besides our basic ‘containersized’ plant design , we have the possibility to adept the power generation island to client specification. In that case we will change our basic full condensing turbine into a back-pressure turbine design. This gives us the possibility to use the exhaust steam out of the turbine to deliver heat to a multi stage water evaporator. In this way salt or brackish water can be turned into valuable potable water or process water. The amount of water which can be produced may vary, based on the chosen values of the exhaust steam of the turbine.

Heating/cooling

Part of our waste to energy solution is to provide heat for district heating, steam for industrial use or even cooling capacity for warehouses. Due to our modular design, our plant design can be modified towards the local requirements and or supplied by our specifically engineered solutions.

On some cases this may even increase the overall system efficiency with 30 – 40%.

More information

Since there are various applications of thermal energy the DutchPowerGroup ‘containersized’ solution can supply thermal energy at different levels, depending on the customers’ requirements. Specifically the low value heat stream (low pressure steam with low temperature such as exhaust steam out of our back-pressure turbine), of our designed plant can be adjusted to such a level where its heat output can be made suitable for practical use. The above mentioned application are all possibilities where our plant can be used as a source deliverer for this heat. The required heat can be used in different types of heat pumps and absorption cooler equipment. For each initiative we can execute a feasibility study to find out if such initiative is viable and profitable.

Advice and education

DutchPowerGroup strongly believes in education as part of the long term solution. We need to educate towards awareness in order to create responsible people!

Addressing the next generation through schools and universities is part of our strategy. Furthermore, leading by example is more powerful than any long term-subvention program. Every day we have the chance to, by making the effort ourselves, influence our surroundings. DutchPowerGroup has, as part of their business model, pledged themselves to financially support each W2E project by contributing to 1 or more local projects. This may involve health care, schooling or other socially beneficial initiatives.

However, not only juveniles are part of that picture, as adults are important influencers TODAY, and also can have direct impact by their behaviour today, managers, directors, workers are a viable part of our educational program as well. Think of presentations, lectures etc.

More information

The DutchPowerGroup solutions are based on technical solutions but also on a change of mind. Both subjects will be addressed by education and courses. The operational crew of our technical installations will get an in-house training, supported by state of the art software simulation programs. With these programs we are able to build theoretical and practical know-how, with the future operational crew and their management. Our long lasting experience has made it possible to develop a training program which includes all operational plant situations to train the future operators to a level where they feel confident to operate their plant.

Entrepreneurial challenge University Twente

We are proud to present DutchPowerGroup as partner for University of Twente during this year’s UT Challenge !

We look very much forward to take part in this exiting event, where experience meets innovation and entrepreneurship of the next generation of promising engineers !

EXPLORE our SOLUTIONS

Since we all in our own way generate waste, one way or the other, we have privately and professionally the possibility to make a difference. We all can support public programs as well as municipal initiatives.

The larger the scale the bigger the impact. Industry as a partner to reduce waste is a very interesting topic. Food industry, wood processing, paper industry and agricultural residues form an integral part of DutchPowerGroup’s sustainable waste management solutions.

Contact

Get in contact with us to see what environmental challenges we can face together! Leave a footprint not only in business but also in your mentality towards the environment.

Commercial

+31(0)85 – 060 8034

References

About

Hans van Tol

CEO

Being a former naval officer on a tanker vessel, I was confronted in an early stage with the way we treated our planet, since those days, the environment has been a constant factor in my career and has made me very much aware about possibilities for change.

As an engineer I look for technical challenges, as a father I look for a better world for my kids. Those combined drives have formed the base for DutchPowerGroup. We are building towards a new , clean planet hopefully together with You.

Mission/vision

Mission: Contribute to a healthy planet by offering advice and deliver (design & build, contract) sustainable solutions for processing residual flows and generating energy (while moving away from fossil fuels).

Vision: Lead by example, be the key advisor on a global scale of waste management in general and re-use solutions and related innovations in particular.